During the 1930s the meat and froze food businesses were booming in the United States. The sale was increased from 10.000,000 lb. of meat, vegetables, fruit, and fish to more than 130.000,000 lb. from 1939 to 1945. Despite this huge spike in sales companies were still concerned with the problem of packing meat and poultry. These products come in irregular sizes they cannot be put into orthodox square packages before being frozen. When they are exposed unwrapped to low freezing temperatures, they sometimes dry out, suffer unsightly “freezer burns.”

In 1937, a French scientist named Maurice Piettre introduced a new wrapping material during a conference on food processing. The process was already working in his native country for refrigerated meats. The material was latex—pure natural rubber altered just enough to be workable. Dewey and Almy Chemical Co. of Cambridge, Massachusetts, tried to adopt the Cryovac process. The company’s researchers set to work devising a commercial method for wrapping poultry and meat in latex. Cryovac means ‘cold and empty’. Meat or poultry to be frozen is wrapped tight in a latex balloon which keeps it from drying out, makes an attractive wrapping.

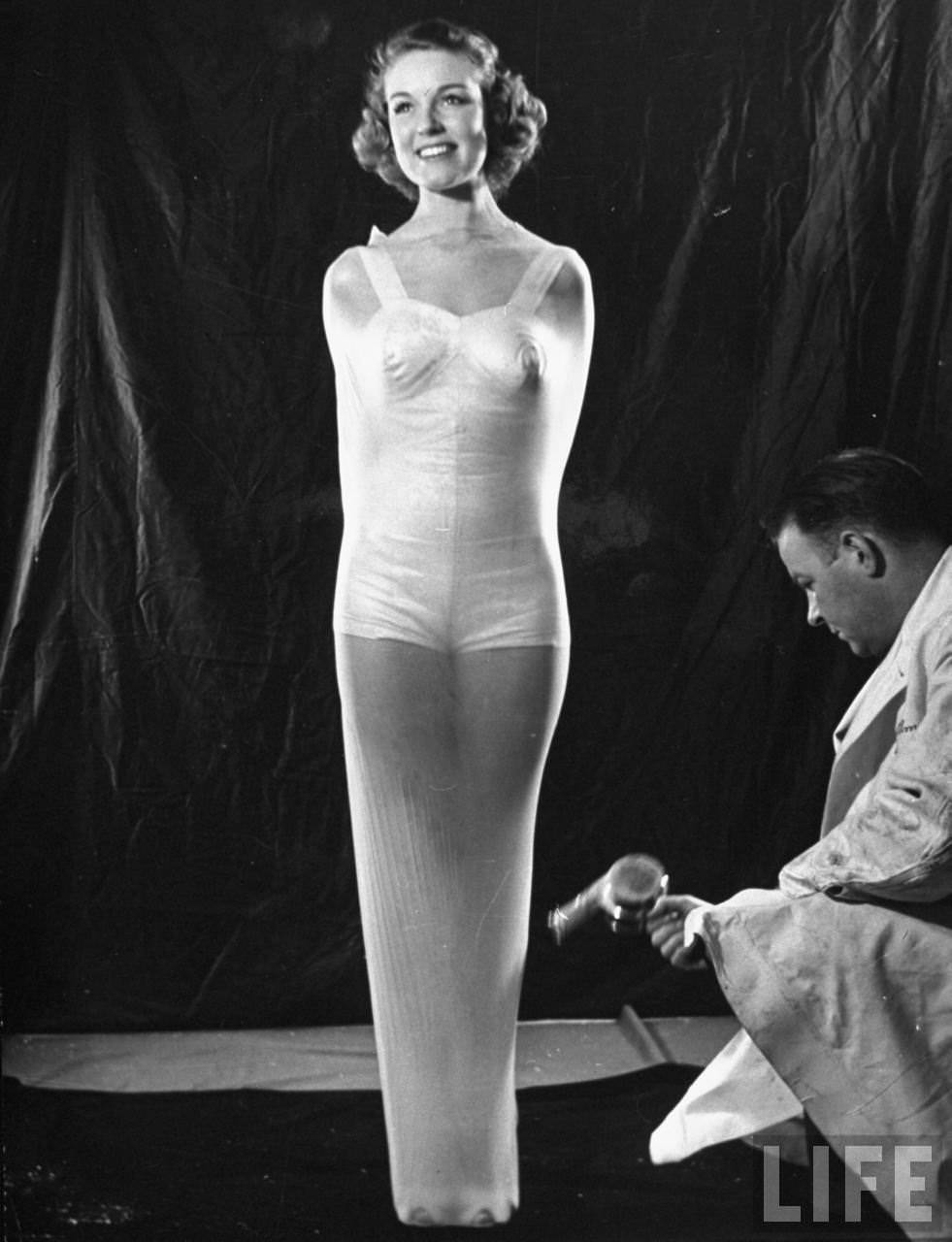

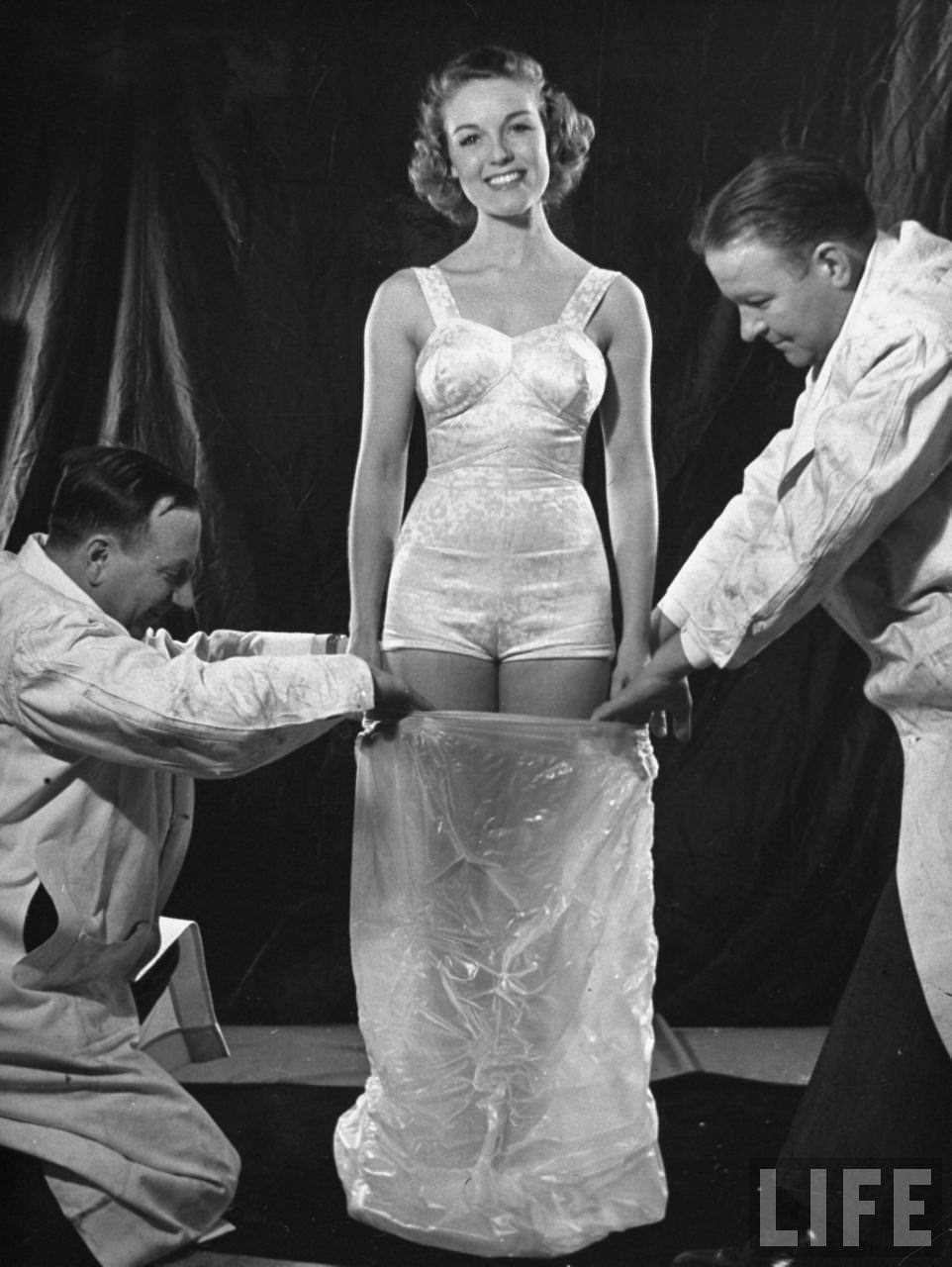

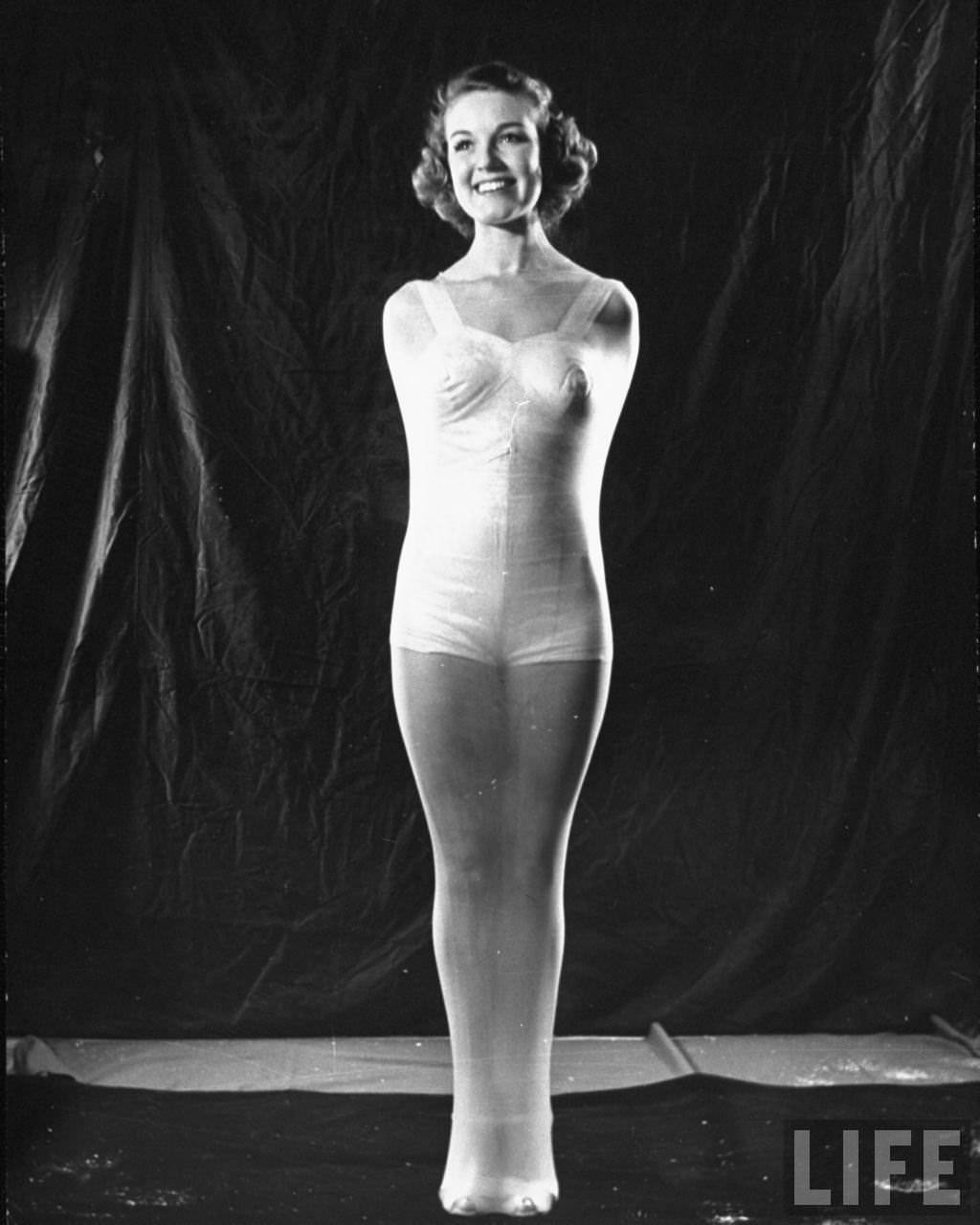

To demonstrate this accomplishment, they sealed a girl in one of their containers. The girl steps into a balloon that has been inflated then chilled so it stays stretched in large size. The bag is tied, air drawn from it, and then sprayed with warm air which causes the latex to shrink.

The Dewey & Almy Chemical Co. had two main lines of business. One is making the compound that canners use to seal tops to cans. The other is making latex meteorological balloons for weather observations. In Cryovac, Dewey & Almy neatly combine their packing and their balloon interests.