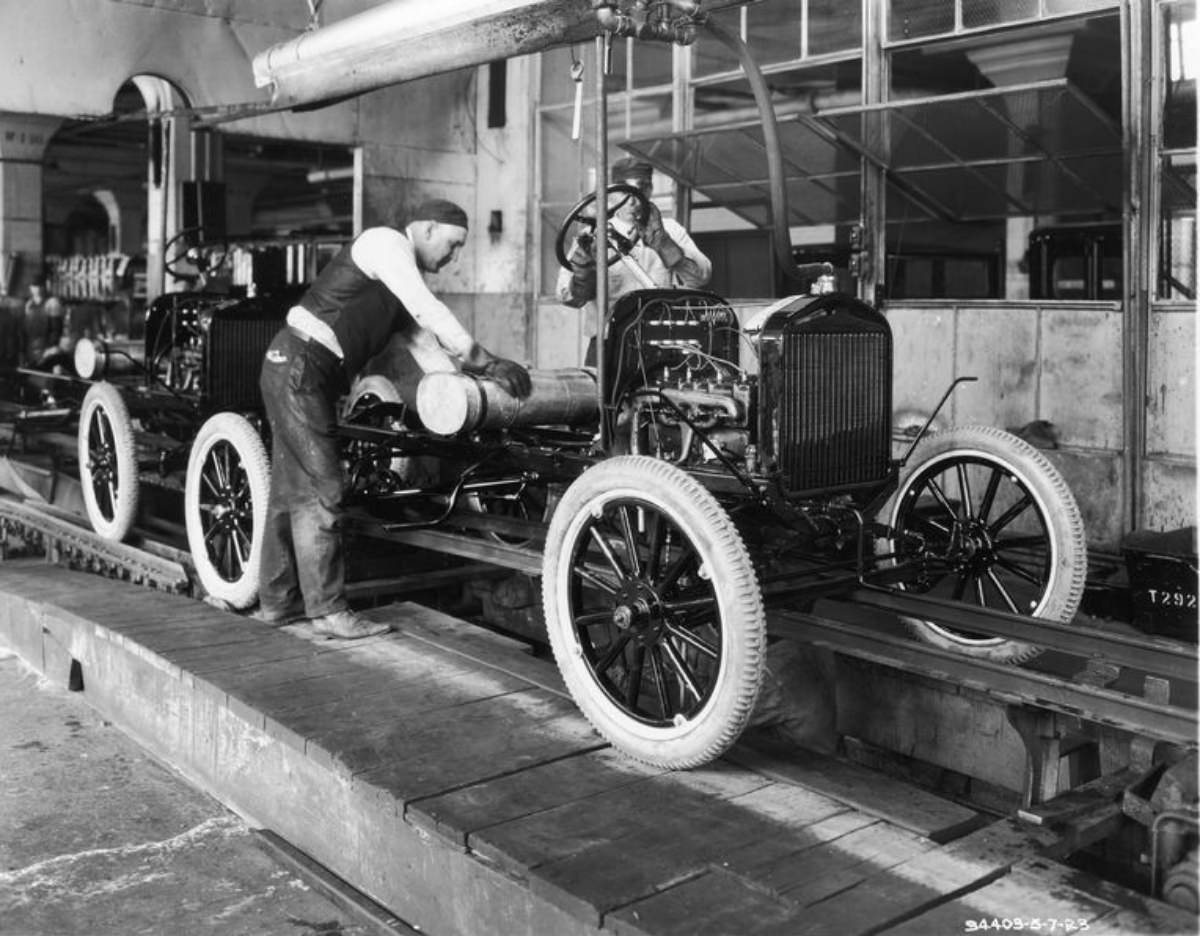

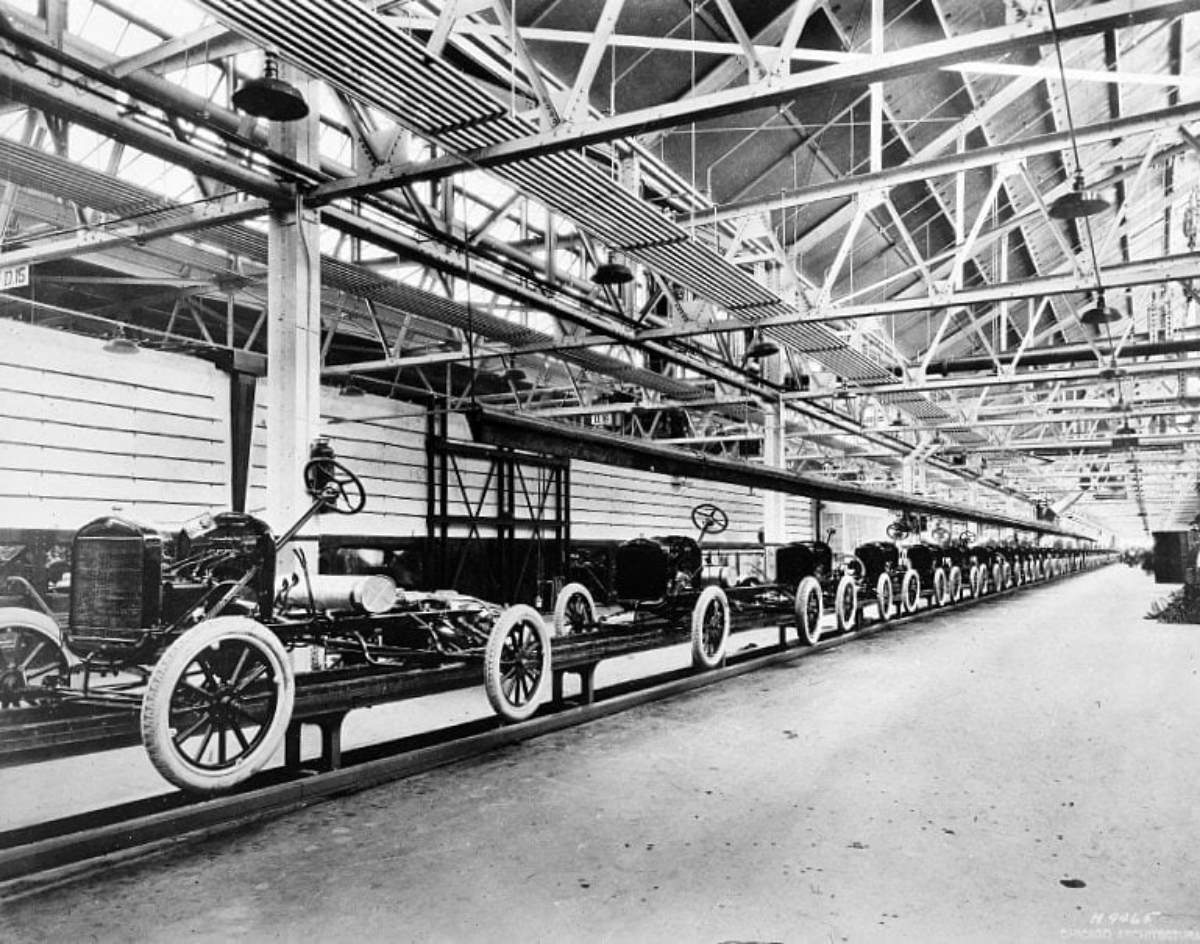

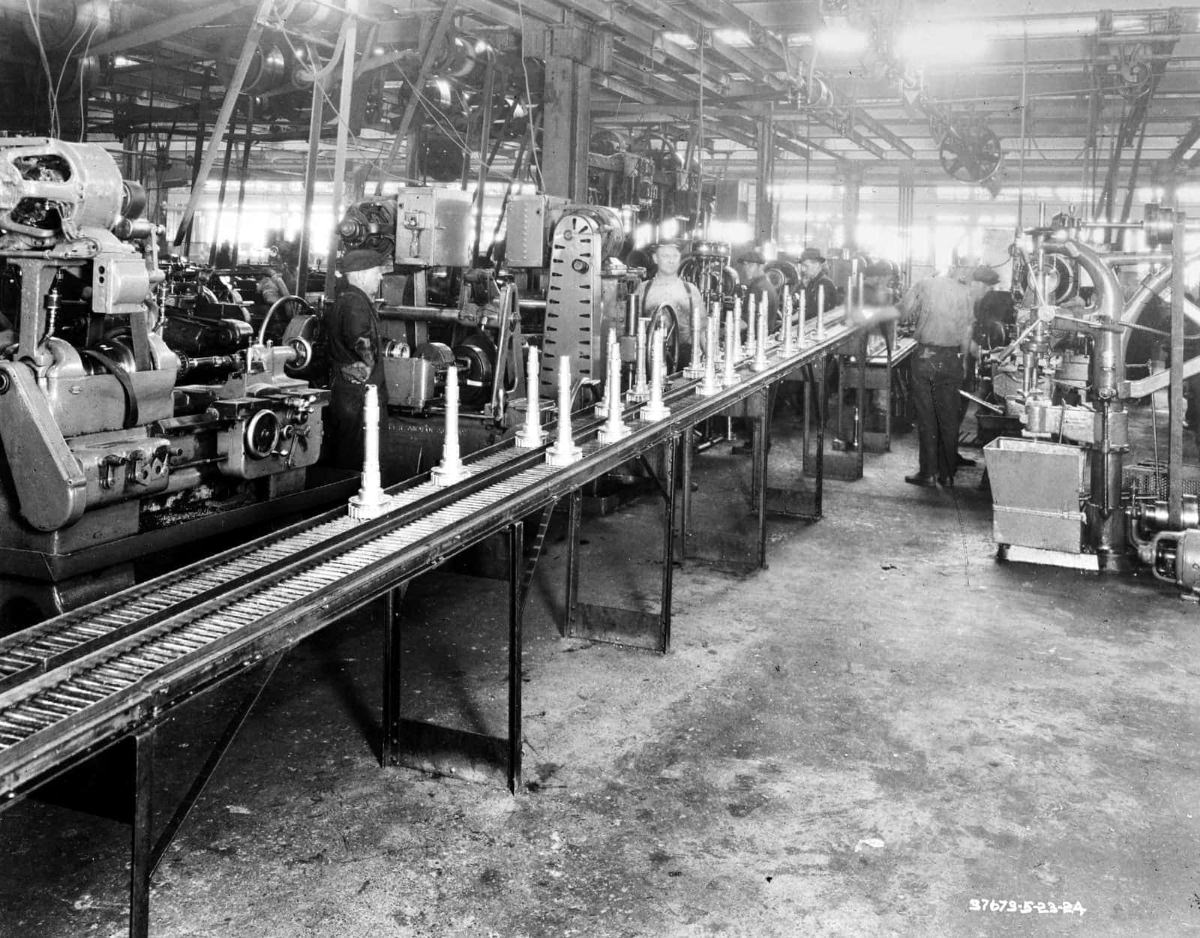

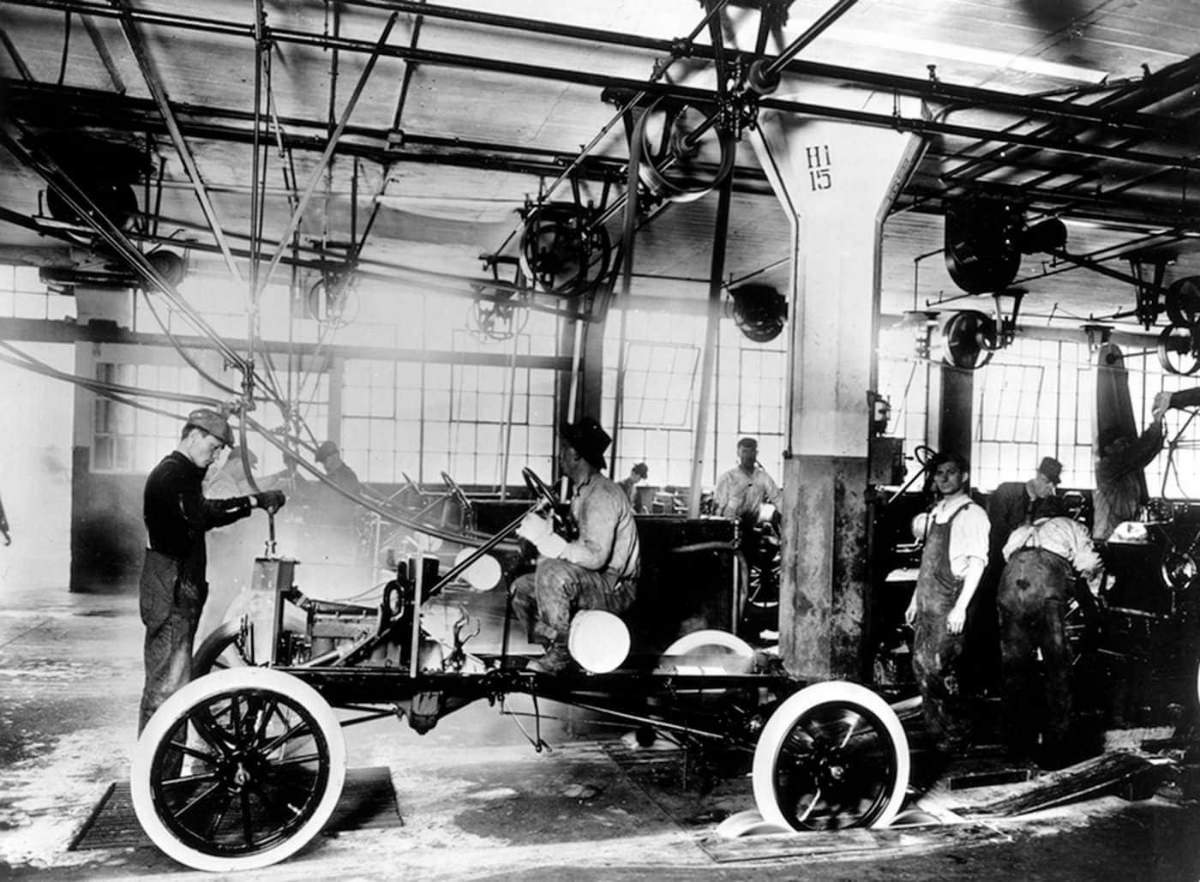

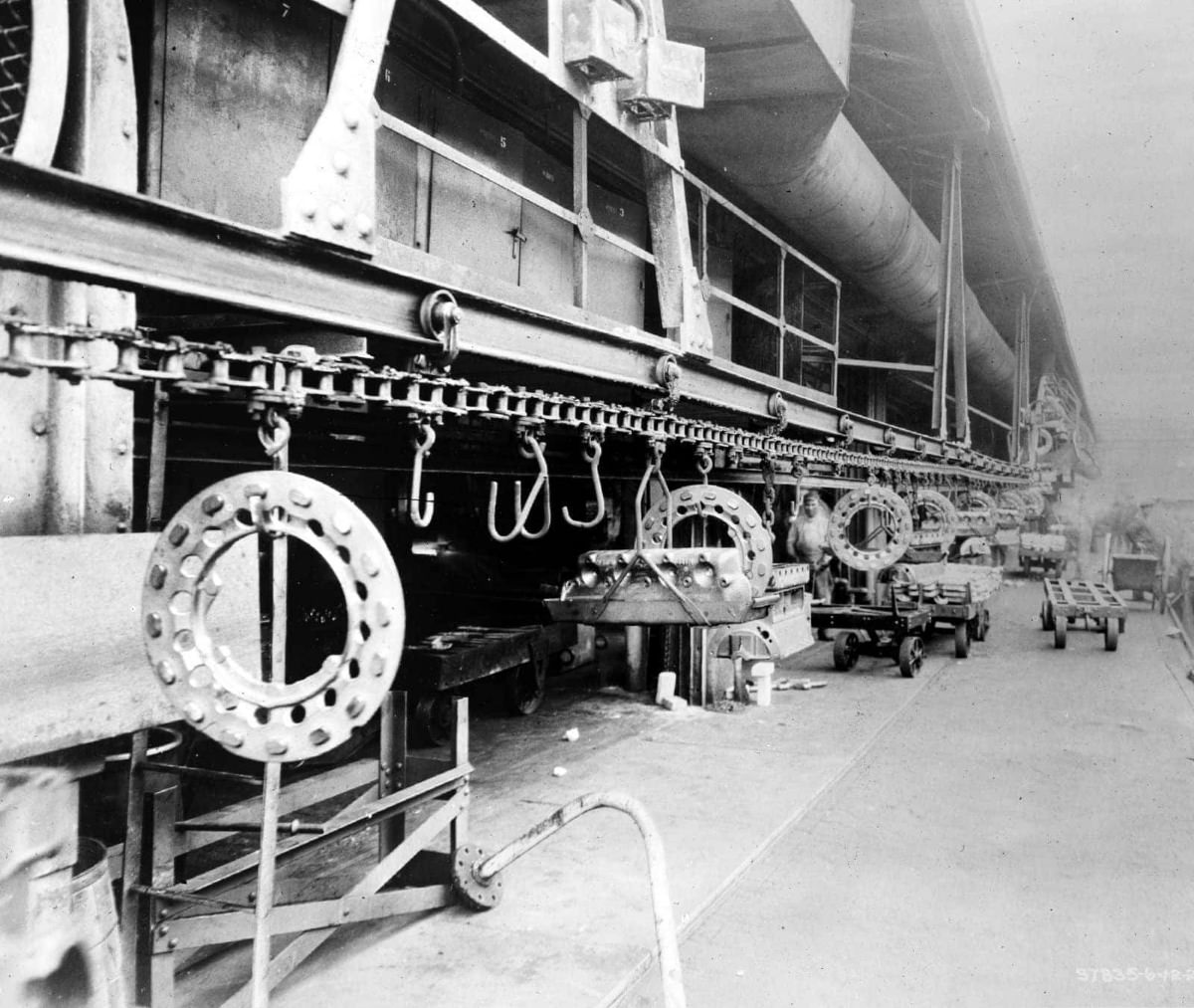

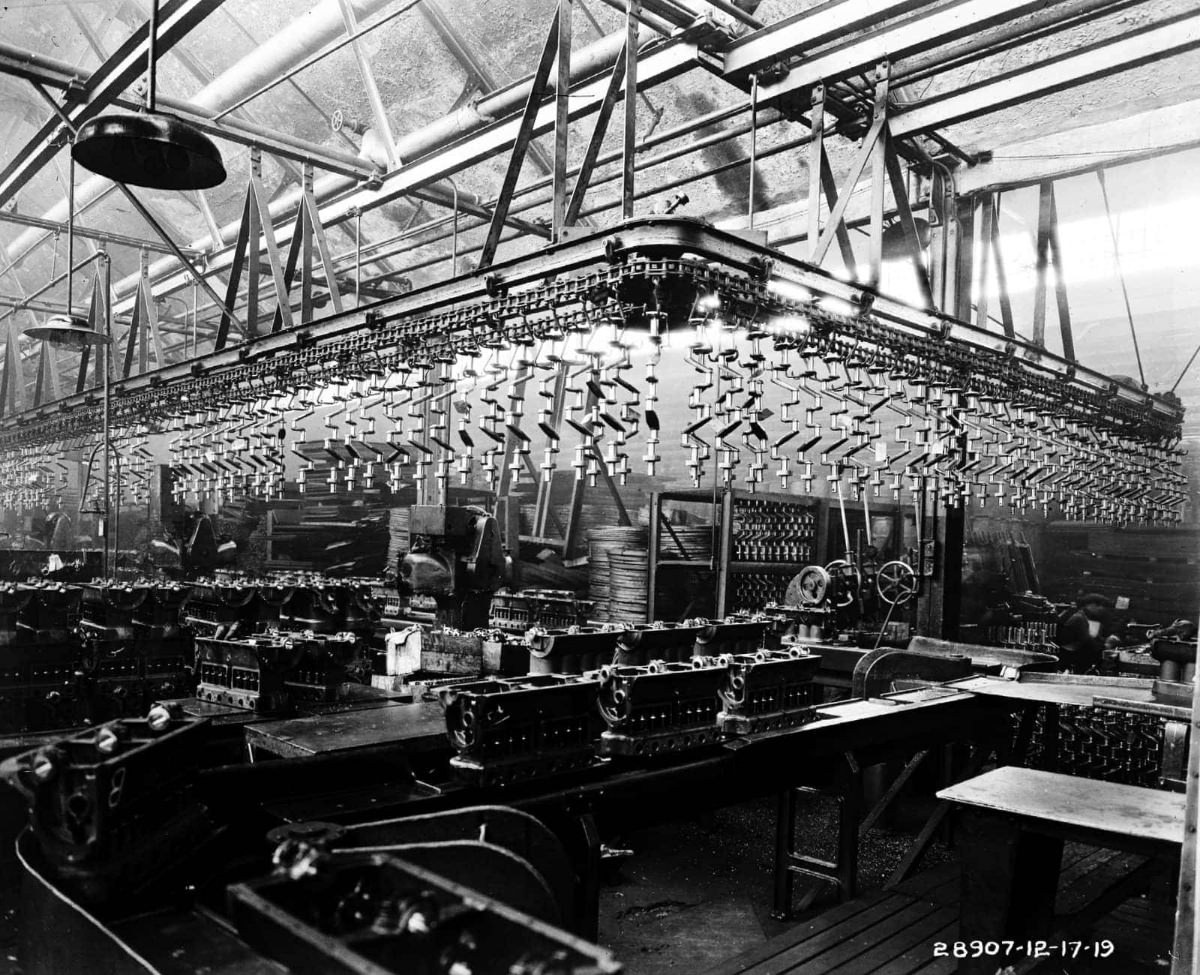

Henry Ford, the visionary behind Ford Motor Company, introduced the world to the assembly line in 1913. His idea was simple, yet groundbreaking: instead of one worker constructing an entire car, each worker would specialize in just one part of the car’s assembly. This strategy divided the process into smaller, manageable tasks, a concept that drastically reduced the amount of time it took to build a car.

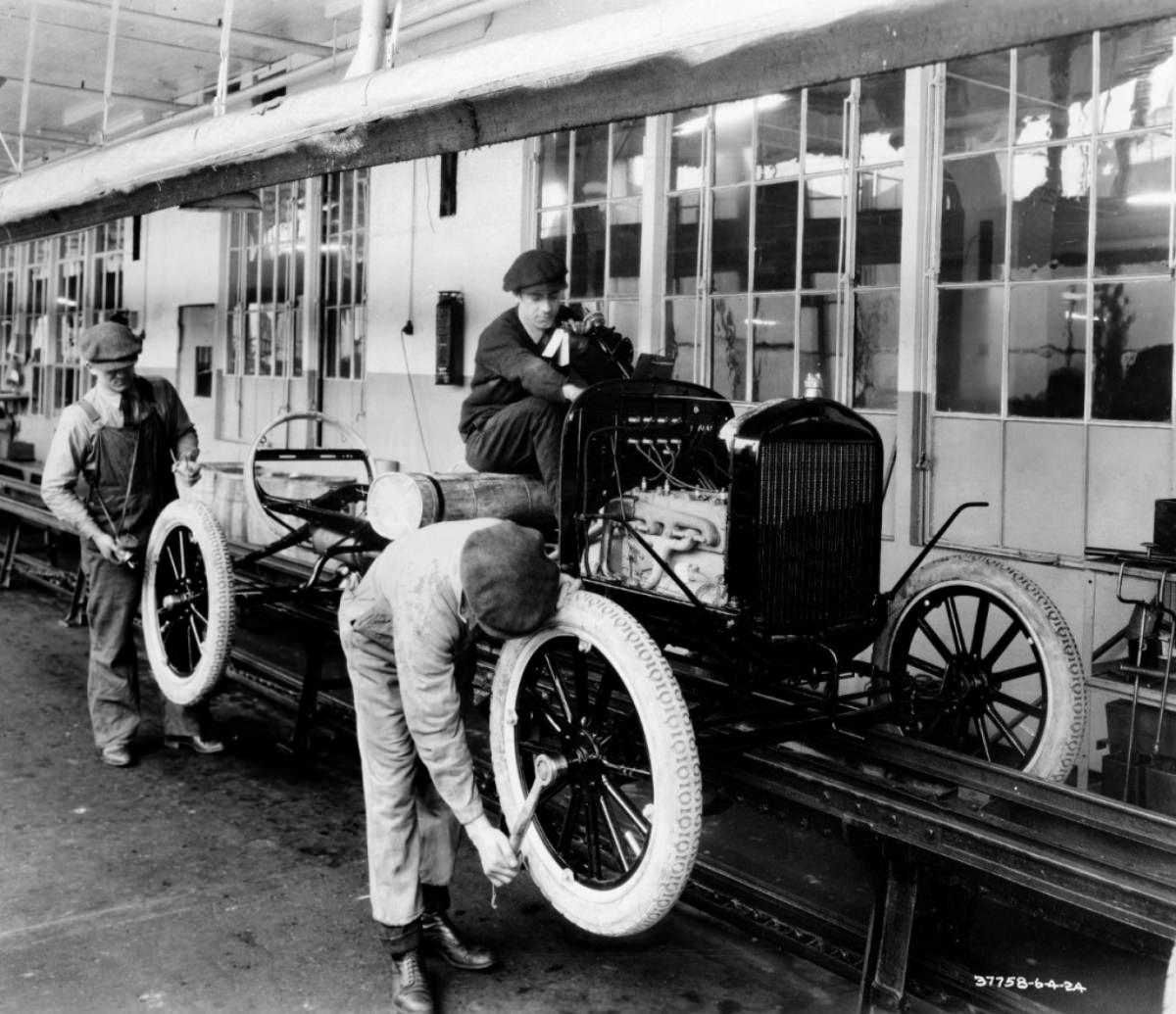

Before the assembly line, it took approximately 12 hours to assemble a single Ford Model T. After the introduction of the assembly line, this process was whittled down to an astonishing 93 minutes! This remarkable decrease in production time allowed Ford to churn out cars at a rate never before seen in the automobile industry.

The assembly line not only revolutionized the speed of production, but it also drastically reduced the cost. The Ford Model T, once a luxury item, suddenly became affordable for the average American. By 1924, the price of a new Model T had dropped to $260, equivalent to about $3,800 in today’s money, all thanks to the efficiency of the assembly line.

However, it wasn’t just the production process that was transformed. The assembly line also had a significant impact on the workforce. Ford’s strategy required less skilled labor, as each worker only needed to master a specific, repetitive task. This shift had both positive and negative repercussions. On one hand, it created thousands of jobs for unskilled workers, leading to an economic boom in regions with Ford factories. On the other hand, the monotony of the work led to high employee turnover.

To combat this, Ford made another revolutionary move in 1914 by introducing the $5-a-day wage, more than doubling the average wage at the time. This not only helped retain employees but also allowed them to become consumers of the very products they were creating.

The assembly lines of Ford in the 1910s and 1920s were a turning point in the industrial era, setting a precedent for manufacturing processes across the globe. They transformed the way products were made, how people worked, and even how they lived, as owning a car became a reality for many.