The Eiffel Tower stands as a defining symbol of Paris and a globally recognized landmark. Its creation in the late 19th century was a monumental achievement in engineering and construction. Built to serve as the grand entrance and centerpiece for the 1889 Exposition Universelle (World’s Fair) – celebrating 100 years since the French Revolution – the tower’s design and construction process involved innovation, meticulous planning, and remarkable execution.

The Design Takes Shape

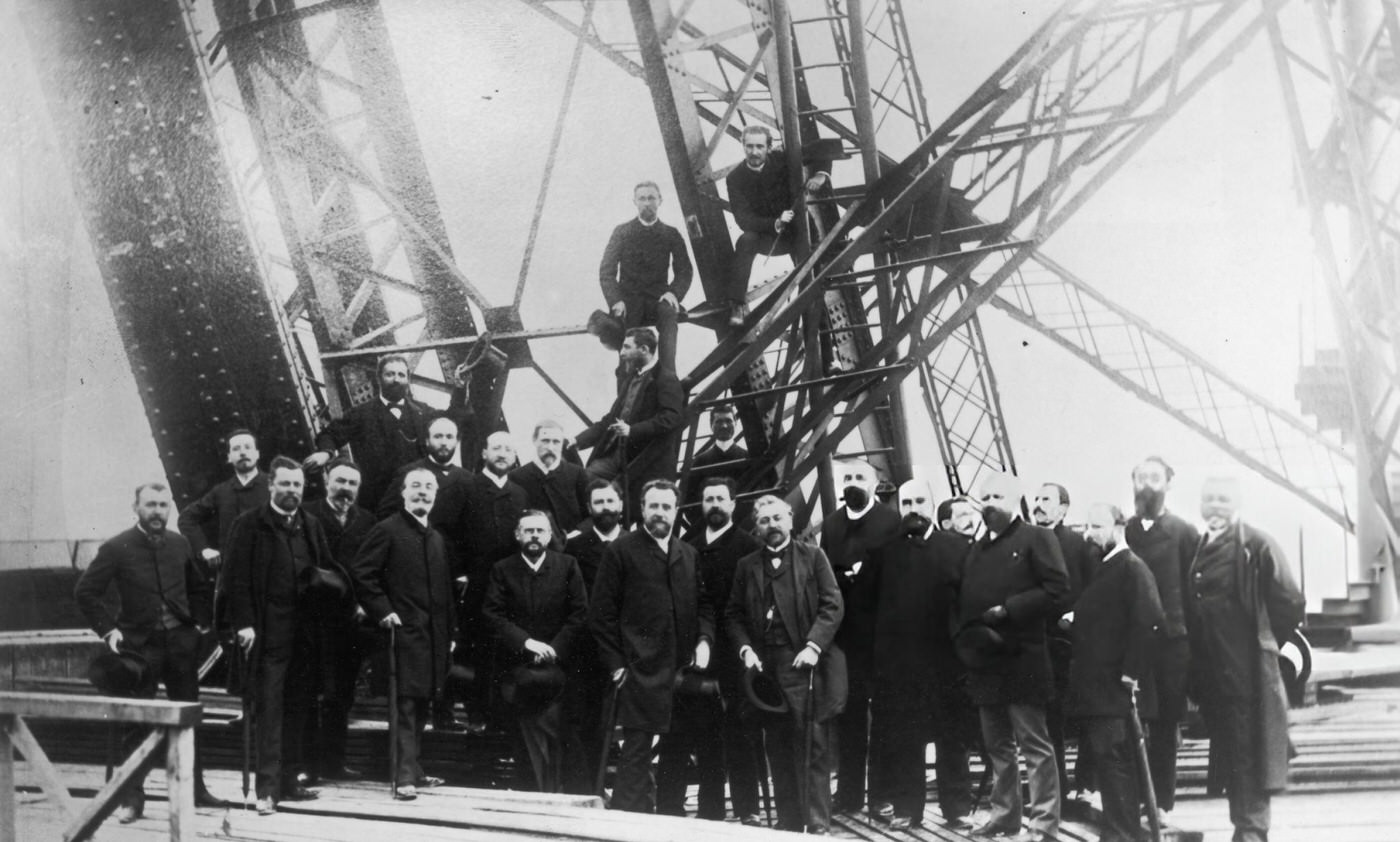

The concept for the tower came from the engineering company owned by Gustave Eiffel, already a celebrated French engineer known for his work on bridges and viaducts. While Eiffel championed and oversaw the project, the fundamental design and the complex mathematical calculations ensuring its stability were primarily the work of two engineers within his firm: Maurice Koechlin and Émile Nouguier. Stephen Sauvestre, an architect working with the company, later refined the design’s appearance, adding decorative elements like the large arches at the base, viewing platforms, and a small domed structure (cupola) at the top to enhance its aesthetic appeal beyond pure engineering. The core design was for an exceptionally tall structure, targeting a height of 300 meters (approximately 984 feet), to be built using wrought iron arranged in an open lattice framework. This lattice structure was key, providing incredible strength for its weight while significantly reducing wind resistance – a critical factor for such a tall tower. The design drew heavily on principles learned from building large iron railway bridges.

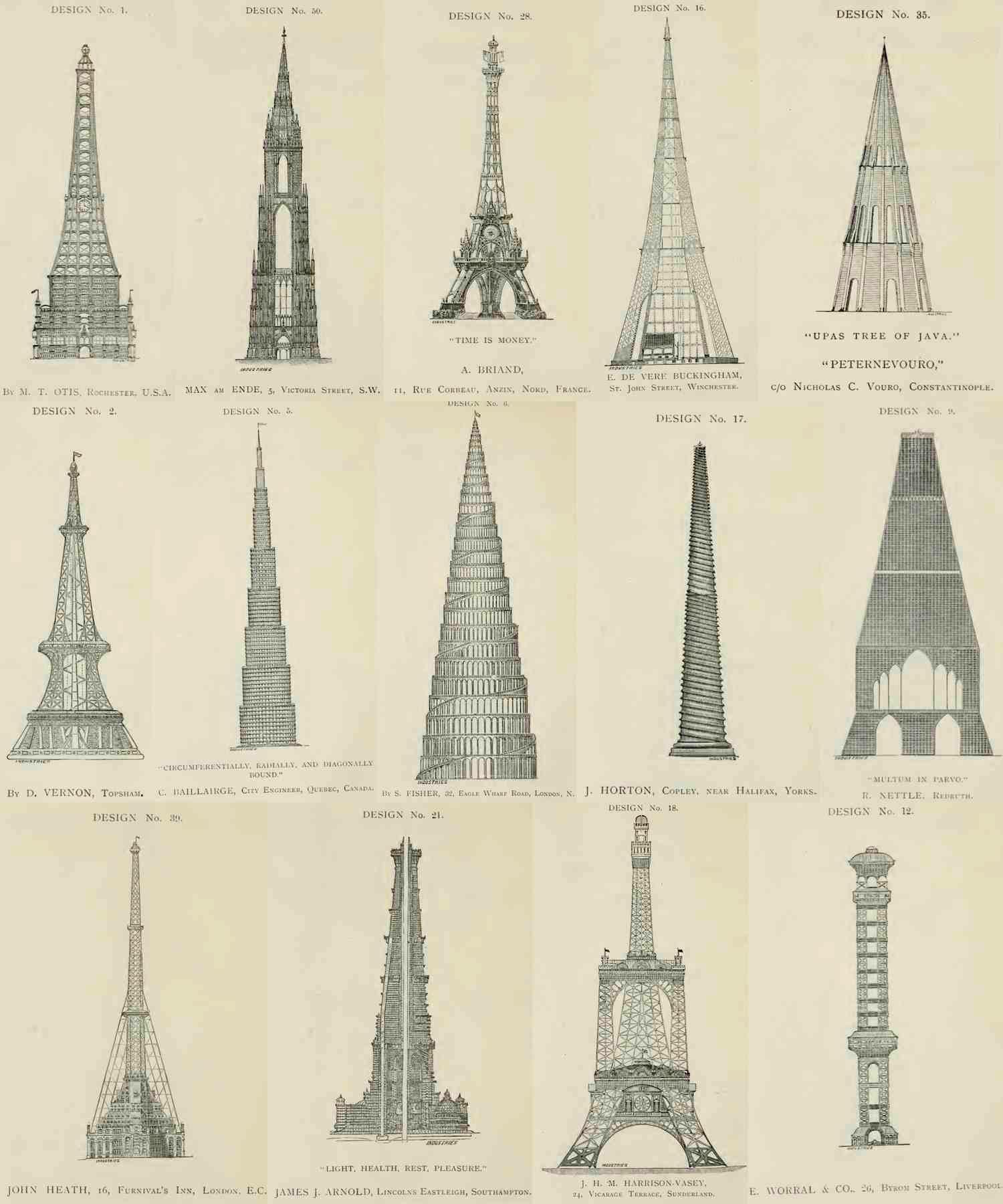

Winning the Project (Bidding Process)

To select a centerpiece for the 1889 World’s Fair, the French government held an open competition in 1886. The main requirement was the design and construction of a 300-meter iron tower on the Champ de Mars. More than 100 proposals were submitted. The design put forward by Gustave Eiffel’s company, rooted in the work of Koechlin and Nouguier, was chosen as the winner. Eiffel’s strong reputation as a leading engineer played a significant role in securing the commission. The contract was officially signed on January 8, 1887. A notable part of the agreement stipulated that Eiffel himself would finance a large portion of the construction costs. In return, he was granted the right to operate the tower and collect all income from ticket sales and restaurants during the exposition and for the next 20 years.

The Chosen Material (Materials – Iron & Rivets)

Wrought iron, specifically a high-quality form produced through the “puddling” process, was selected as the main construction material. This choice was based on wrought iron’s known strength, its ability to withstand stress and vibration better than the more brittle cast iron, and its resistance to corrosion when properly maintained (i.e., painted). The tower’s open lattice design, using thousands of interconnected iron beams and struts, allowed for a structure that was both incredibly strong and relatively light for its immense size. The final tower incorporated over 18,038 individual prefabricated wrought iron pieces. These pieces were meticulously joined together using approximately 2.5 million rivets. The process of riveting involved heating each rivet until it was glowing red, inserting it into precisely aligned holes in the iron pieces to be joined, and then hammering the protruding end flat to form a second head. As these hot rivets cooled, they contracted, pulling the iron components together with tremendous force, creating exceptionally strong and rigid connections.

The high-quality puddled wrought iron needed for the tower was sourced primarily from the Pompey forges in the Lorraine region of eastern France. Strict quality control measures were likely in place to ensure the iron met the demanding specifications required for such a novel structure. Not all rivets used were identical; different sizes and types were employed depending on the specific structural connection points and the stresses they needed to bear. The precision extended beyond just the location of rivet holes; the angles and shapes of connecting pieces had to be exact to ensure the complex geometry came together correctly on site.

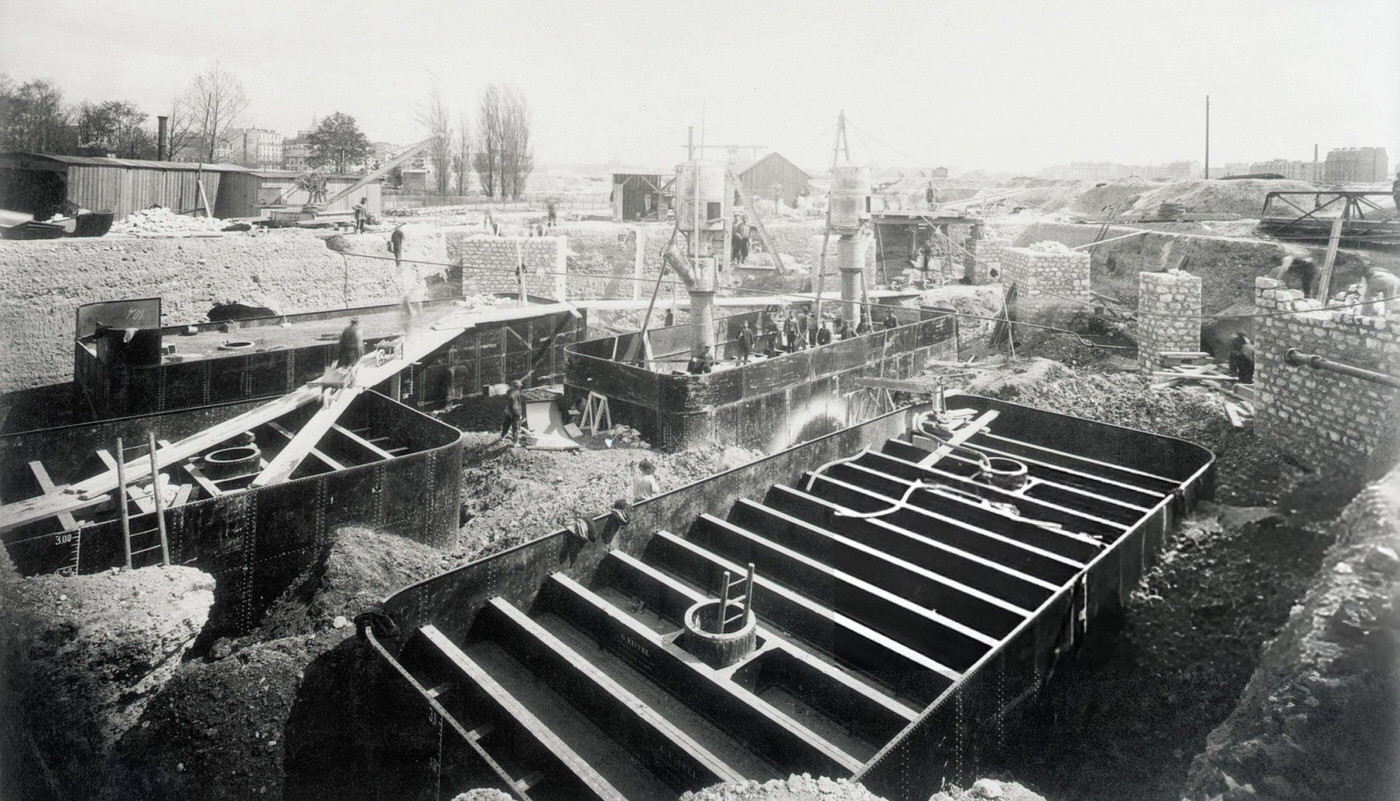

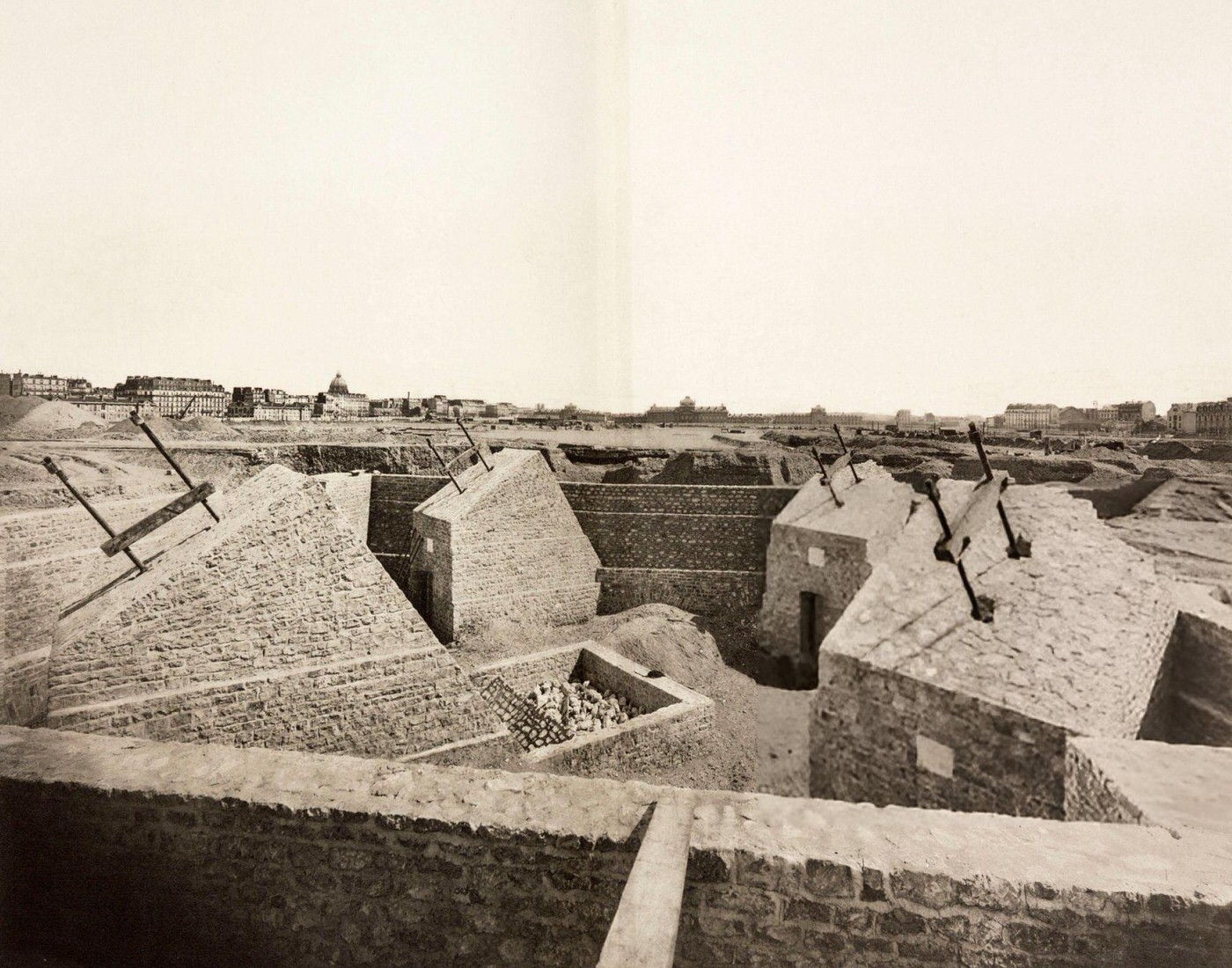

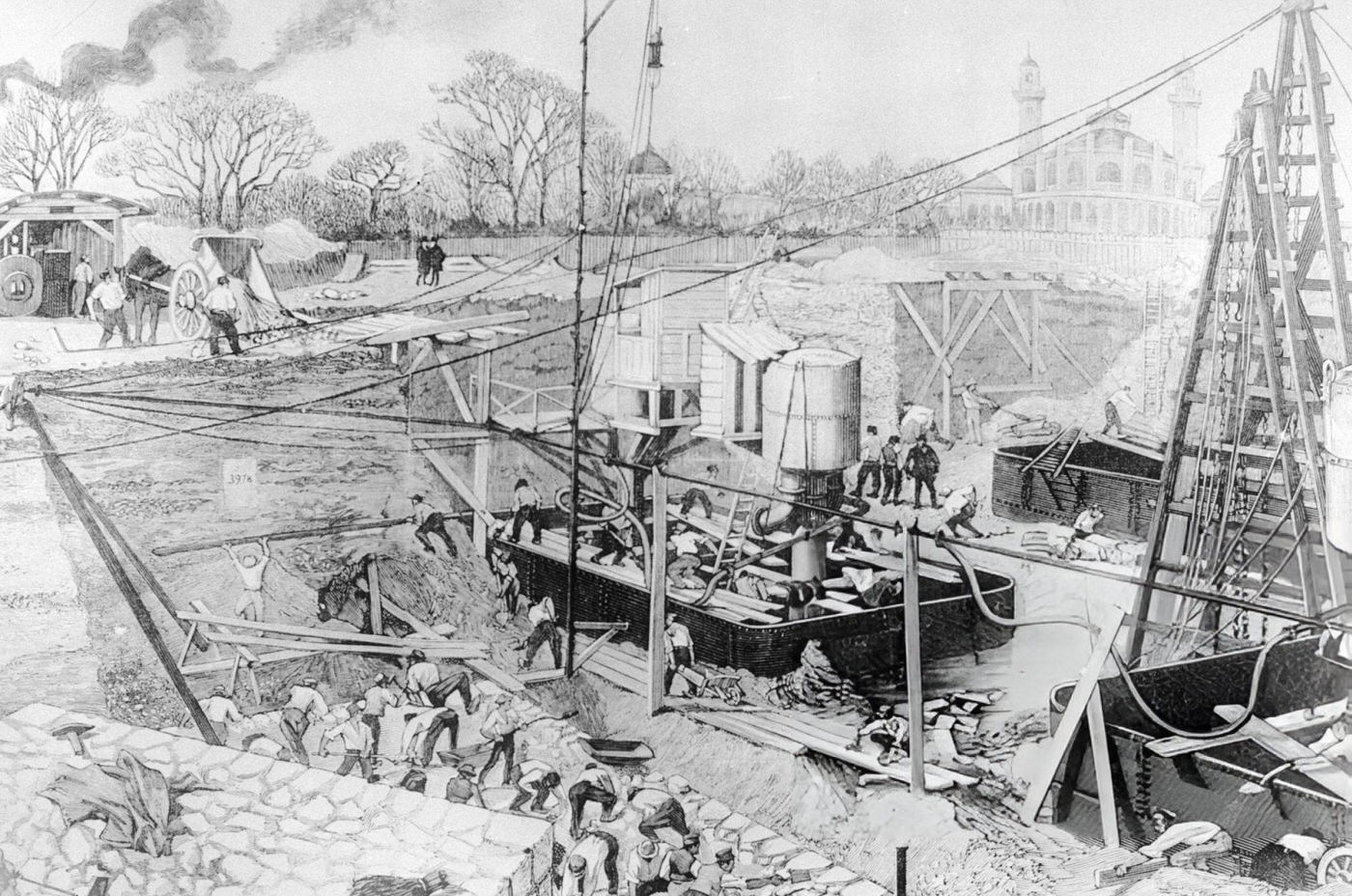

Laying the Groundwork (Materials & Construction – Foundations)

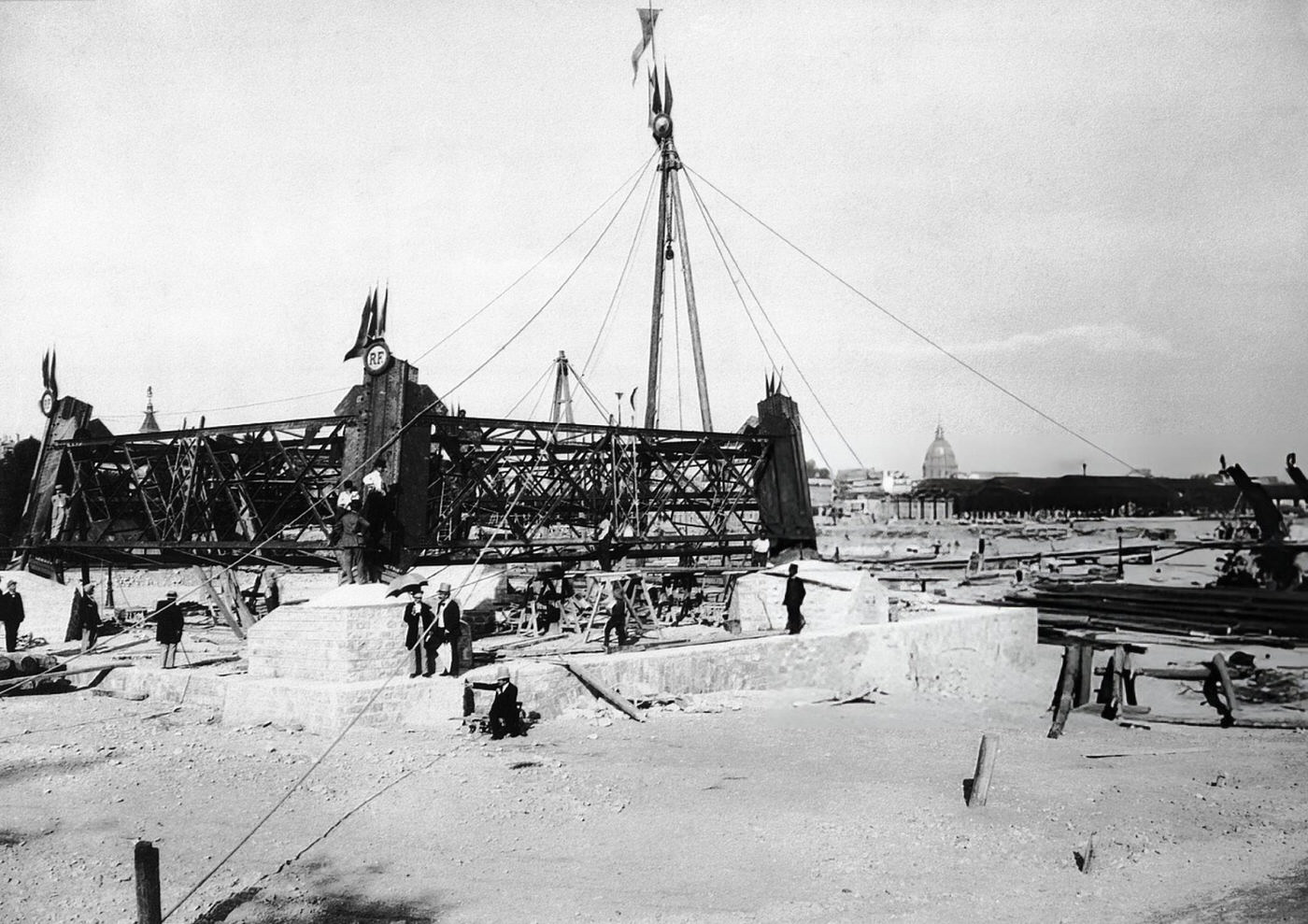

A structure of the Eiffel Tower’s proposed height and weight demanded extremely robust foundations. Building these presented significant engineering challenges, particularly as the site was close to the Seine River, meaning the ground was softer and the water table was high. Immense concrete foundations were laid deep underground for each of the tower’s four massive legs. These concrete blocks, in turn, supported precisely cut blocks of limestone upon which the ironwork would rest. For the two legs located closest to the river, construction required the use of watertight chambers called compressed air caissons. These large metal boxes were sunk into the ground. Air pressure inside was kept higher than the water pressure outside, preventing water from entering and allowing workers (known as caissoniers) to dig out the soil and build the masonry foundations deep below the water level. Achieving perfect levelness across the tops of all four foundation piers was absolutely essential. To ensure this, powerful hydraulic jacks were incorporated into the base of each leg’s support structure. These allowed engineers to make minute adjustments to the height of each leg support, guaranteeing the tower’s first level was perfectly horizontal before construction proceeded upwards.

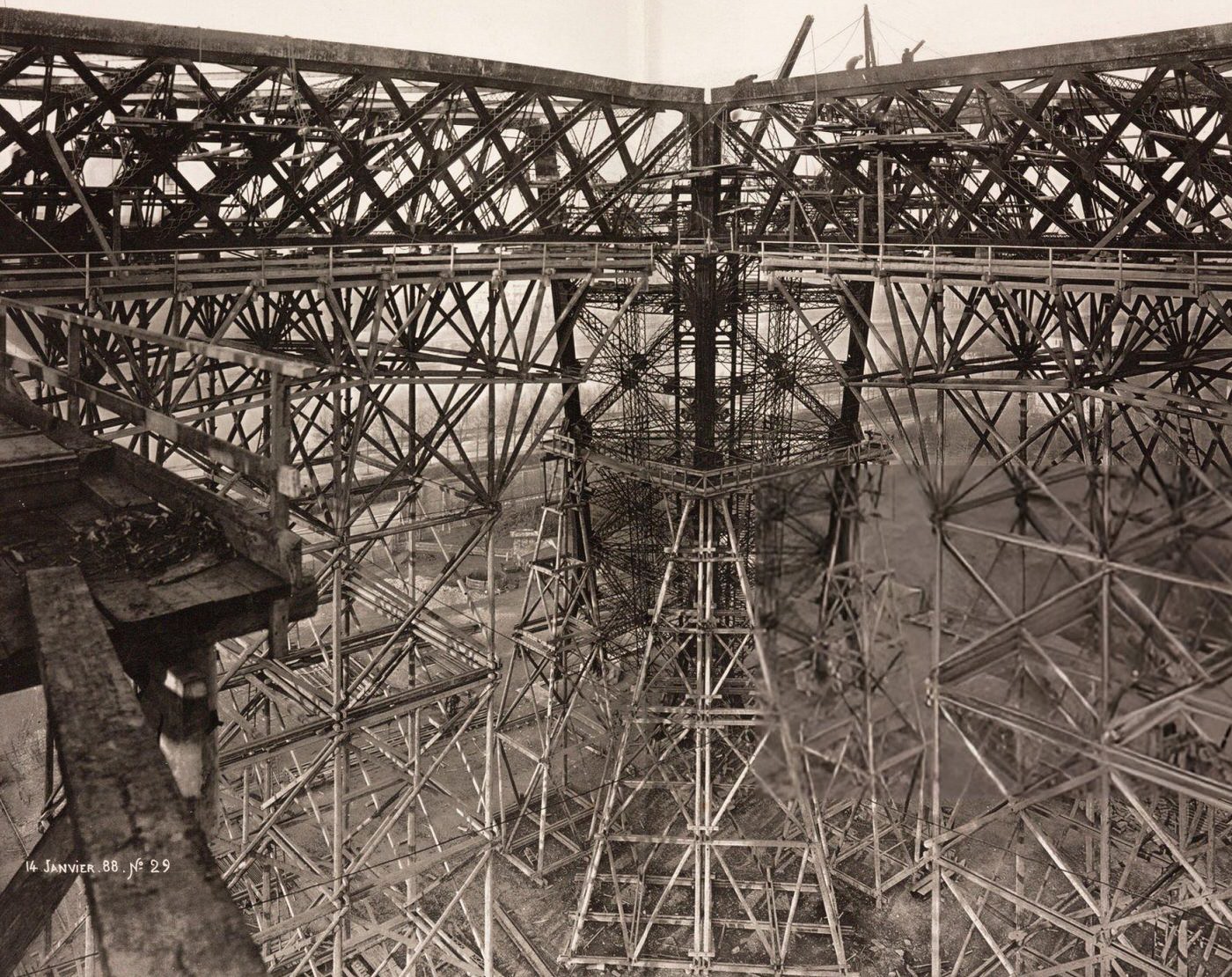

Precision During Assembly

Ensuring the tower rose straight and true required constant checking. Engineers on site used tools like theodolites (precision optical instruments similar to telescopes used by surveyors) to monitor the alignment of the legs and levels as construction progressed. Despite the incredible accuracy of the prefabricated parts, minor adjustments were sometimes needed high above the ground. Temporary bolts could be used to hold pieces together while rivet holes were slightly enlarged using conical reamers to achieve perfect alignment before the permanent hot rivets were inserted. Joining the four massive, inwardly curving legs together precisely at the first level was one ofthe most critical and challenging phases of the entire assembly process, requiring careful coordination.

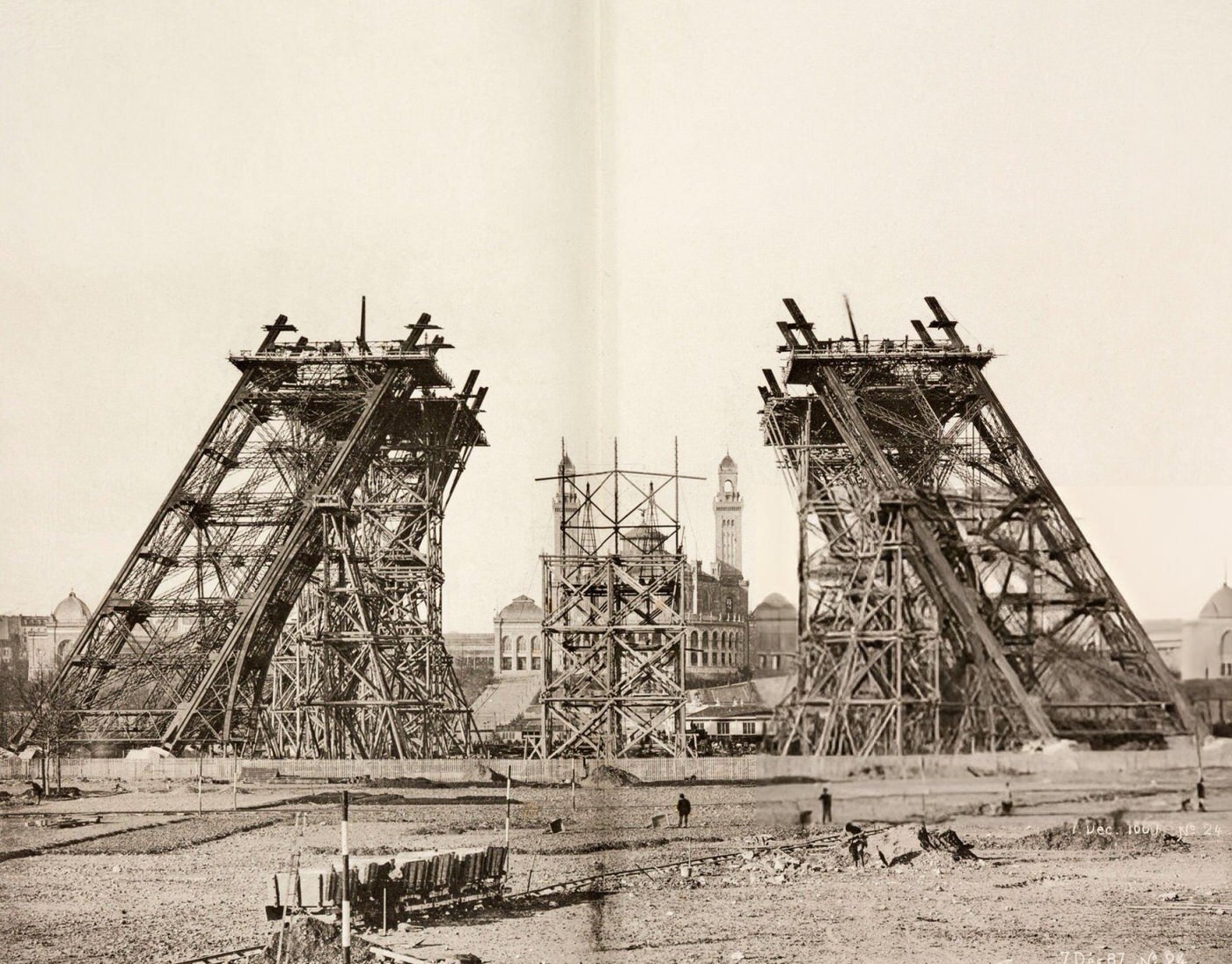

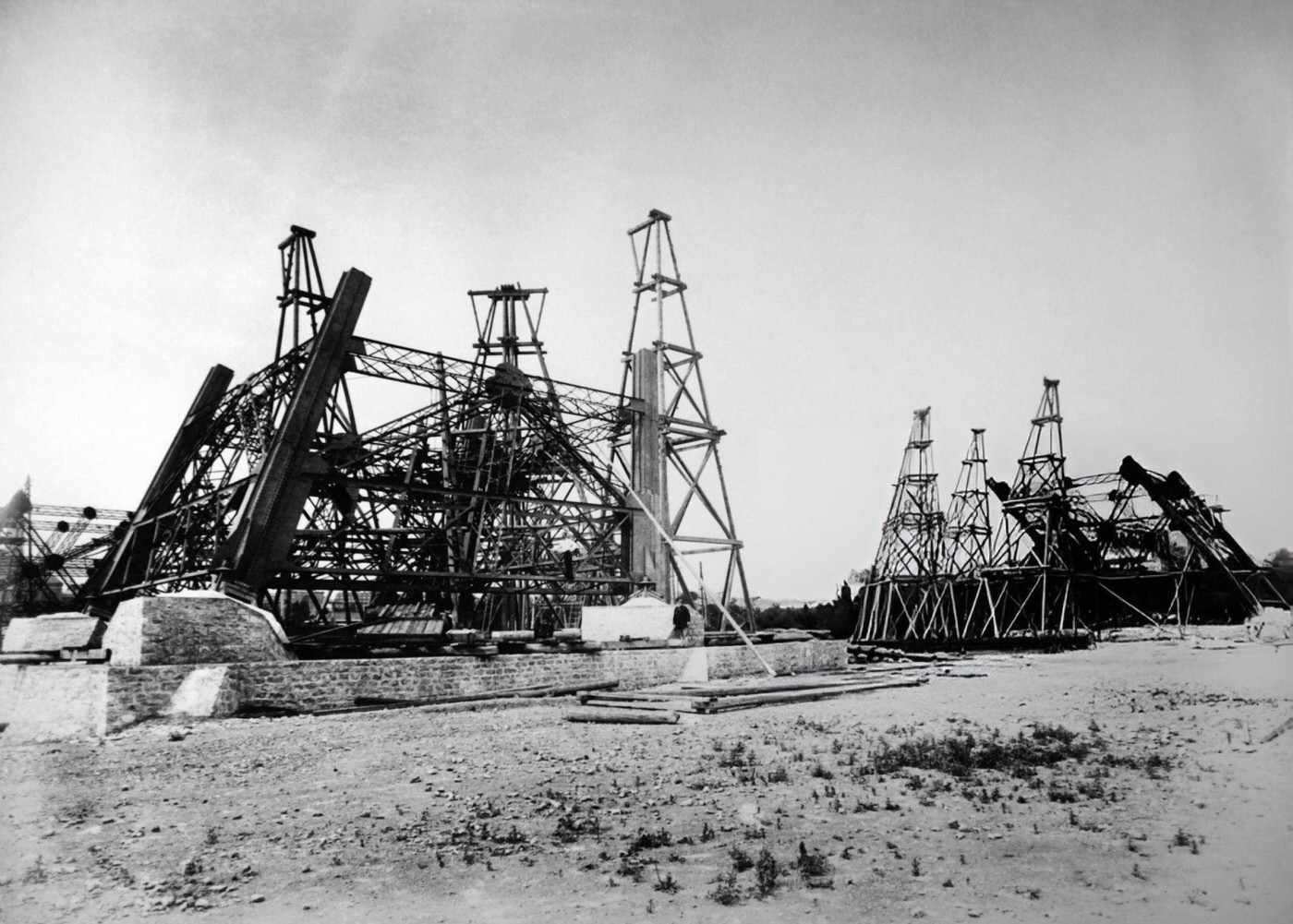

Building Upwards (Construction Process – Assembly)

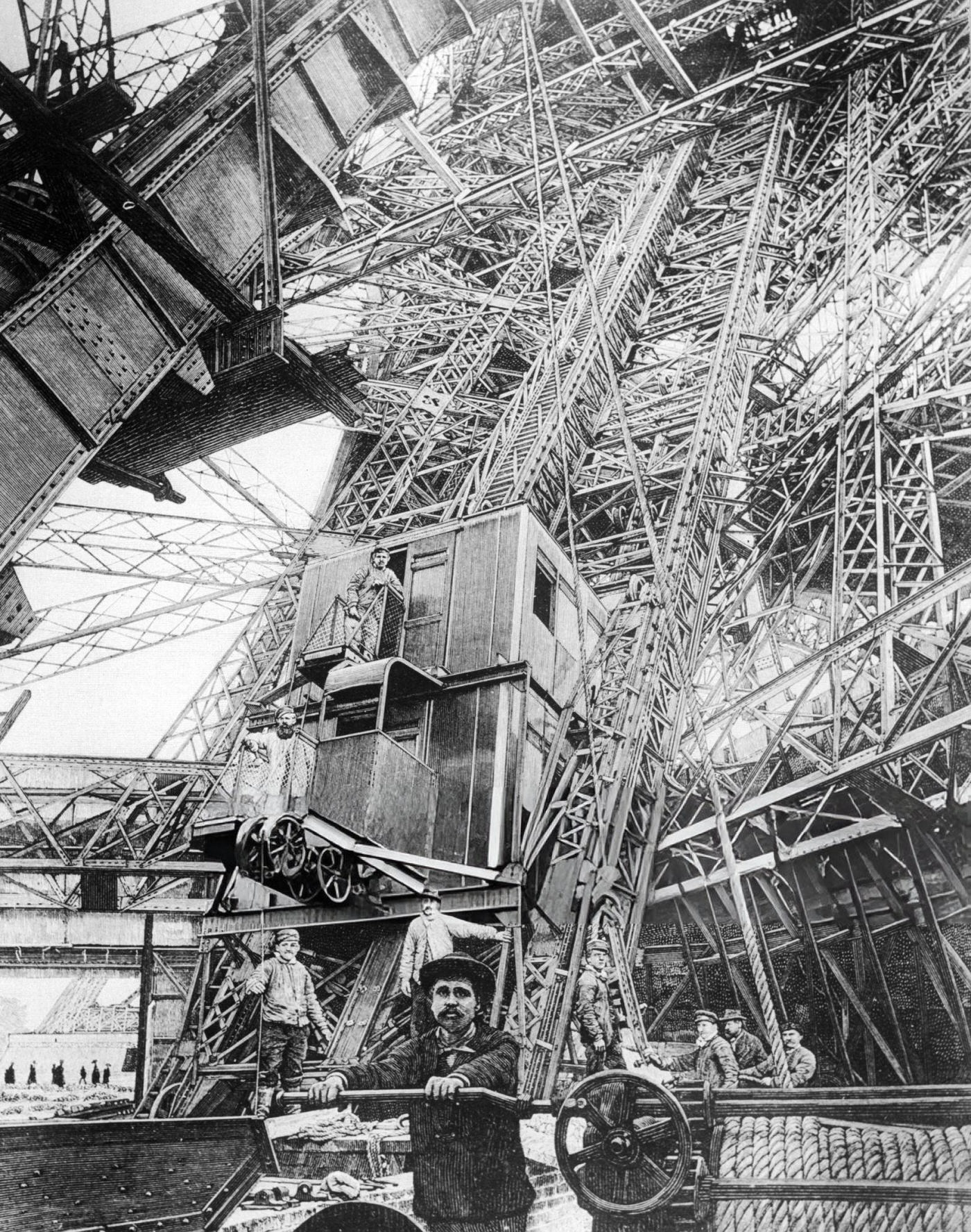

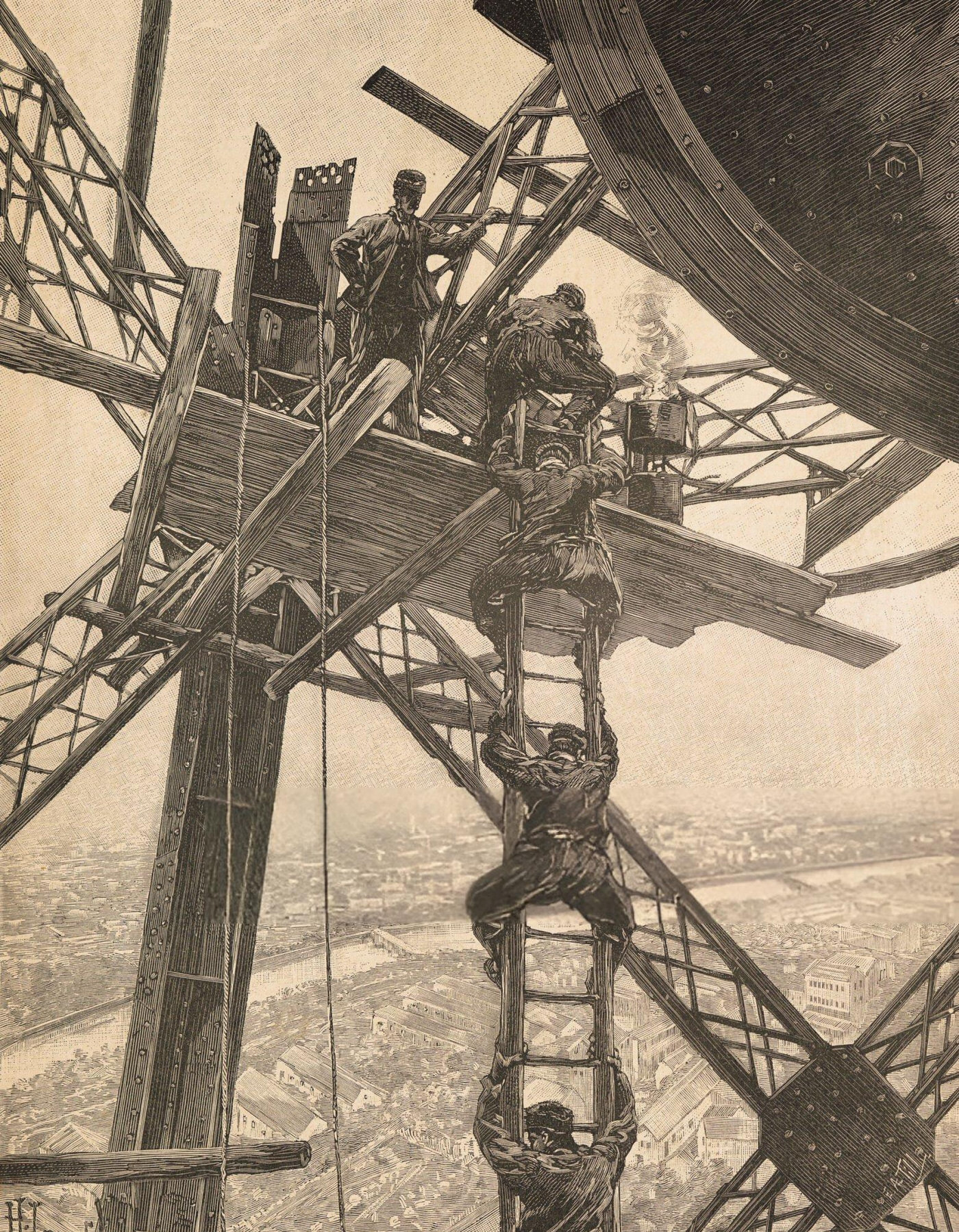

A key element enabling the rapid construction was the prefabrication of all the iron components. Every single one of the more than 18,000 parts, complete with precisely located rivet holes (accurate to within a tenth of a millimeter), was manufactured at Eiffel’s factory in Levallois-Perret, on the outskirts of Paris. Each component was carefully numbered according to detailed engineering drawings – over 1,700 general drawings and 3,629 detailed drawings were produced. These finished pieces were then transported to the Champ de Mars site. To lift the heavy iron girders and lattice sections into place, specialized creeper cranes were used. These cranes were installed on the tower legs themselves and climbed upwards as the structure grew. The assembly high above Paris was carried out by teams of skilled workers, nicknamed “skywalkers” (voltigeurs). The riveting process required coordinated teams of four men: one heated the rivets in a small portable forge, another inserted the hot rivet into the hole, a third held it steady on one side, and the fourth hammered the end flat. This precise assembly method continued relentlessly, piece by numbered piece.

The Workforce and Conditions

At the peak of construction, a workforce of around 250 to 300 skilled workers were employed directly on the Champ de Mars site. These included specialist ironworkers accustomed to working at height and teams expert in the hot riveting process, which required strength, timing, and coordination. They worked long hours, often in difficult weather conditions. Wind, in particular, posed a significant challenge and potential danger when lifting and maneuvering the large iron sections hundreds of feet above the ground. Small portable forges were used on the structure itself to heat the rivets close to where the assembly teams were working.

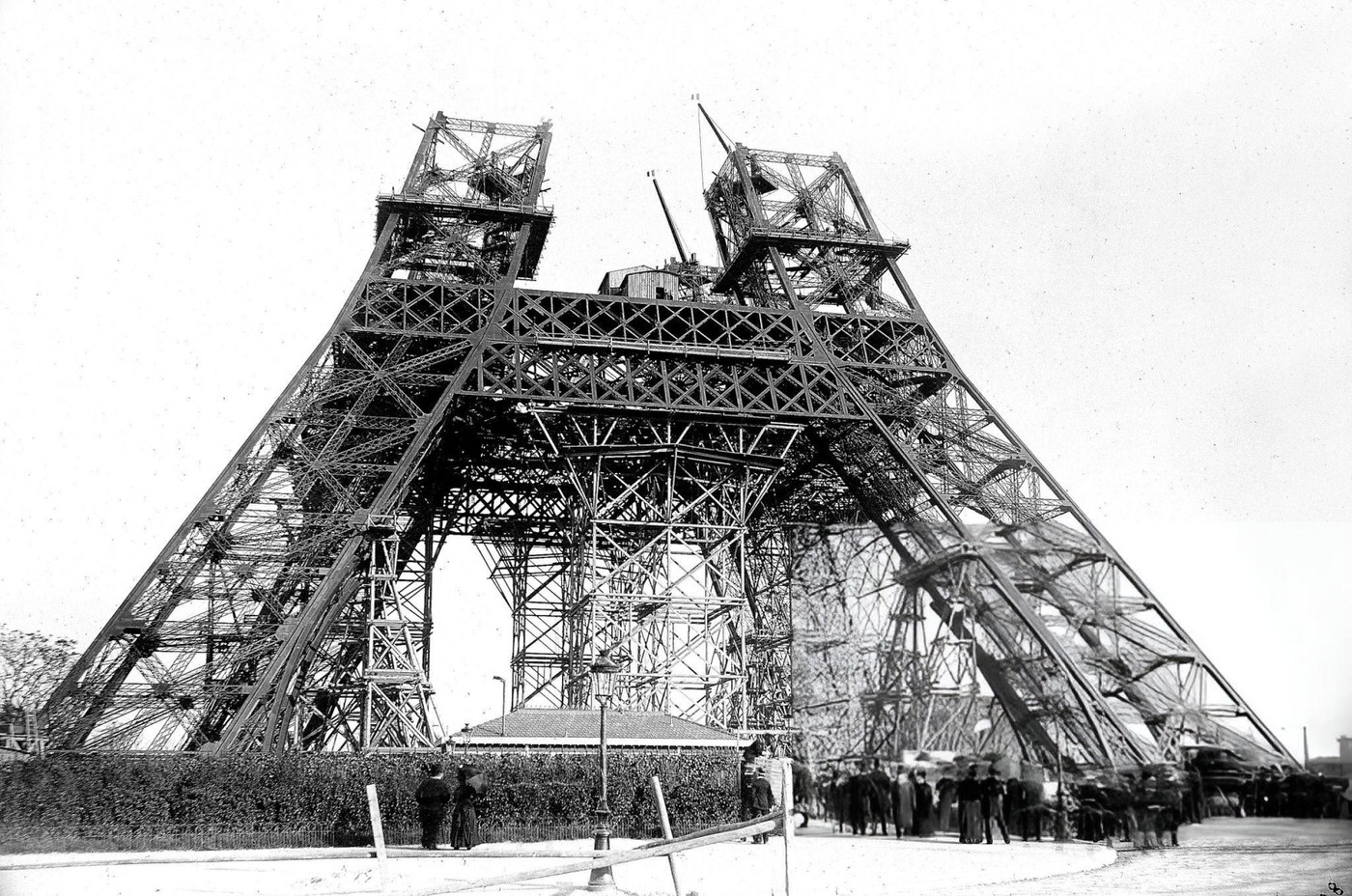

Reaching New Heights (Construction Process – Stages & Safety)

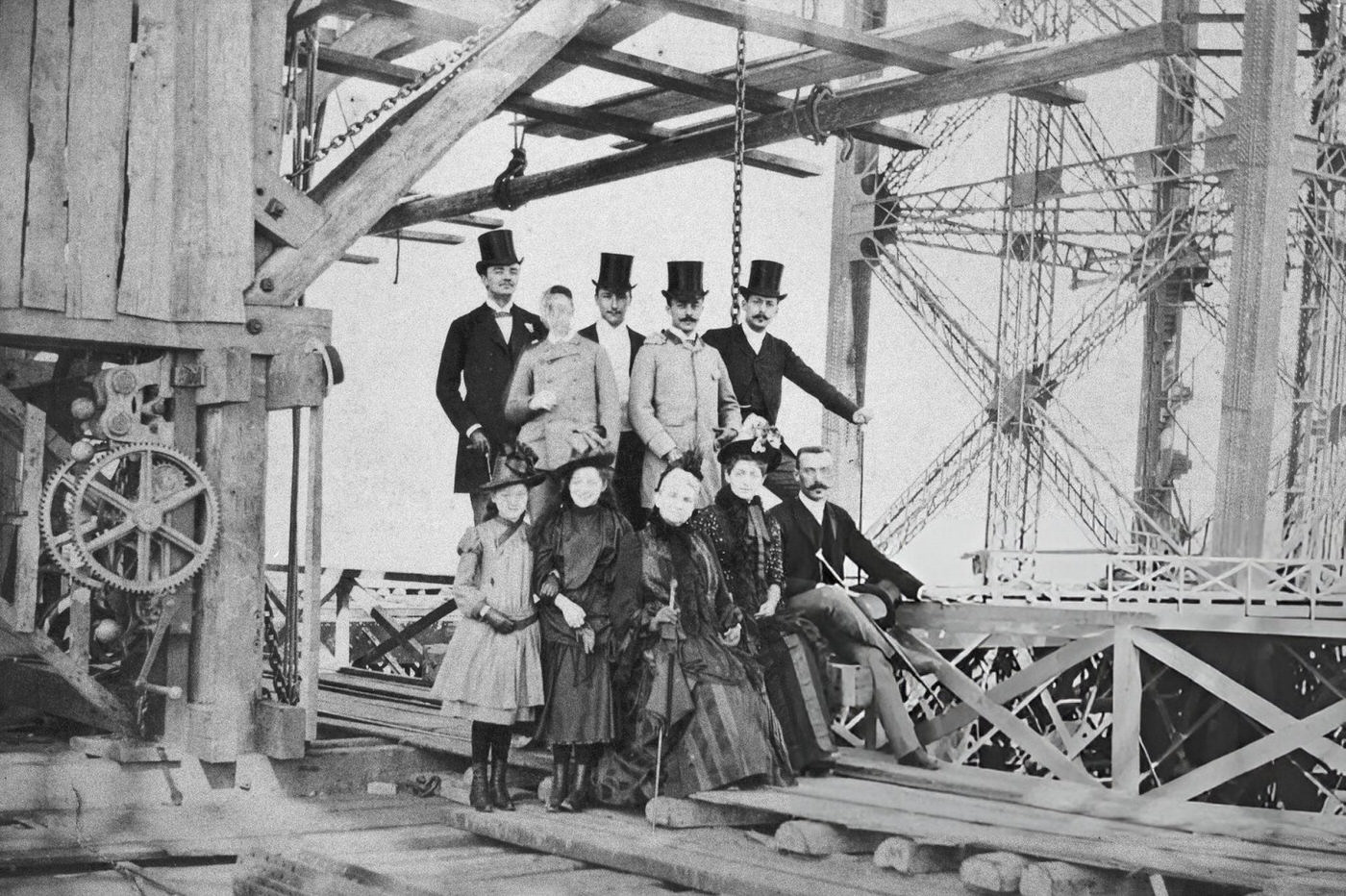

The tower rose in stages. Initially, the four angled legs were supported by massive timber scaffolds until they curved inwards and joined together at the first level platform. Once this connection was made, the structure became self-supporting, and construction continued upwards to the second level, and then to the smaller platform near the top. Lifts (elevators) were integral to the design for visitor access. Their installation began as the tower sections were completed, initially using systems from the American company Otis, later supplemented or replaced by French designs. The speed of construction was remarkable for such a complex and unprecedented project; the entire tower was completed in just 2 years, 2 months, and 5 days, finishing in March 1889, ready for the opening of the World’s Fair. Despite the dizzying heights and inherent risks of 19th-century construction, the project had a relatively strong safety record. Gustave Eiffel implemented safety measures like movable staging, guardrails, and screens. While minor accidents occurred, only one fatality was officially recorded at the site itself, and this happened when a worker was off-duty. Once assembled, the entire iron structure was painted, initially in a shade called “Venetian red” or reddish-brown, primarily to protect the wrought iron from rusting.

Gustave Eiffel also incorporated specific features into the final design at the very top. Below the public observation deck, he included a small laboratory space for meteorological and astronomical observations, as well as equipment for wireless telegraphy experiments. Above the public level, Eiffel built a small private apartment for his own use, a secluded perch high above Paris integrated into the structure completed in 1889. The initial layer of “Venetian Red” paint applied upon completion was put on by hand using brushes, a massive undertaking covering the vast surface area of the intricate ironwork.